Thanks for a good discussion guys. Once my current transom saver goes out, I’ll be switching to the Wedge design. As others have mentioned, the transom takes a much harder beating on the water than it would on any trailer ride.

IDO » Forums » Fishing Forums » General Discussion Forum » Great transom saver

Great transom saver

-

August 9, 2012 at 2:12 pm #1090965

I think both sides have given a good argument either way here but let me just offer these items up:

– Just because your transom get’s just as bad if not worse stresses imparted in the water doesn’t mean you don’t want to limit the stresses you see while trailering. Even if the stress on the water is greater, it doesn’t mean that a lower stress out of the water isn’t harmful.

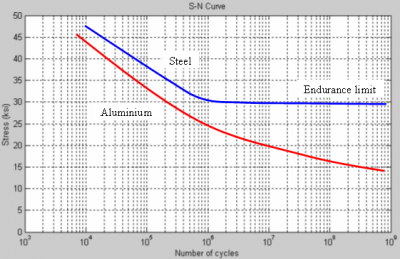

– With steel, as long as you keep the stress low (under it’s Endurance Limit), you can go an infinite number of cycles stressing the material without failure but other materials, like aluminum (anybody have an aluminum transom? An Aluminum Jack Plate?) will fail eventually no matter the stress based on number of cycles.

– I would say that I spend 95% of the day or more on the trolling motor where my big engine is at rest. My transom certainly sees more duration of stressing during trailering than it does on the water. And who’s to say the nature of the stress is the same in-water vs. out of water? Maybe, maybe not.

– I just recently tried the wedge and I think the motor bounces around way more than it ever did with my transom saver.

August 9, 2012 at 2:41 pm #1090978

August 9, 2012 at 2:41 pm #1090978Quote:

Very good discussion. My mind hasn’t been changed though.

That is because you are old and stubborn.

August 9, 2012 at 2:44 pm #1090979How do you know how much stress is on a transom at trolling speed ??? Exactly how much stress is there pushing a 17′ or 21′ boat through water ? How much is there when trailering down a highway ? I would like to see some supporting numbers from your analogy. I would bet a couple months wages, there is more “stress” on the transom when trolling, than when trailering down a MN highway…

I will agree wanting to limit unneeded “bouncing” down the road is a good thing (it can’t hurt) which I believe the wedge does also, as does the traditional transom poles. Just make sure your keepers are on the corners correctly, to keep the boat “firmly” on the trailer.. or your really defeating the intended purpose with the pole

I will agree wanting to limit unneeded “bouncing” down the road is a good thing (it can’t hurt) which I believe the wedge does also, as does the traditional transom poles. Just make sure your keepers are on the corners correctly, to keep the boat “firmly” on the trailer.. or your really defeating the intended purpose with the pole  August 9, 2012 at 2:47 pm #1090983

August 9, 2012 at 2:47 pm #1090983Quote:

Quote:

Very good discussion. My mind hasn’t been changed though.

That is because you are old and stubborn.

Skeptical. I know what my eyes tell me and there’s nothing but opinions and heresay on this thread. Hardly the evidence needed to change my mind. I also tend to trust experience above all. Mine and others. My transom saver has been on my rig since 1998. Transom is fine and rams have never had an issue in 14 years. I think its far more likely transoms are built so well now that you dont see failures seen years ago. I also think that company is using transom as a buzzword to sell product.

No matter what I do see the usefulness in this product.August 9, 2012 at 3:03 pm #1090990I don’t doubt this product works as advertised. Both this product and the “old bent-arm” transom savers do the same thing. One is just longer than the other and mounts at the bottom of the motor unstead of up by the trim motor. both products keep the motor from bouncing and creating stress on both the motor and the transom.

That said, I will still use the old bent-arm design. Why? Because the wedge product isn’t long enough. I have a steep driveway and when pulling out or backing in, I have to have my motor at a certain angle so the skeg doesn’t drag. The m-y wedge doesn’t work for me from that respect. The other reason is that frankly, I’m getting old and forgetful. If I have a big, clunky old TS around and in my way all the time, it’s a reminder to put in on. It’s also right there when I put the drain plug in, so I remember to take it off. I’d be afraid of forgetting the wedge. Although I’ve seen people forget the old style too.

Hey Kooty…Ask Weber what happened to his old transom saver. Clunk!…Oops! Is all I will tell you!August 9, 2012 at 3:21 pm #1091002

Clunk!…Oops! Is all I will tell you!August 9, 2012 at 3:21 pm #1091002For the record, I completely agree with Suzuki on this one. The reason this product is working for these customers is I suspect their transoms on these new rigs are strong enough to take the pressure. Put one of these on a 1992 Alumacraft and you will wreck the transom inside one year. This is no different than what we did in the early 90’s. Stick a piece of 2×4 in between the motor and transom. Been there – done that!

-J.

August 9, 2012 at 4:08 pm #1091025

Quote:

That is because you are old and stubborn.

Not the Suzuki I know.

August 9, 2012 at 4:10 pm #1091029

August 9, 2012 at 4:10 pm #1091029Quote:

Quote:

That is because you are old and stubborn.

Not the Suzuki I know.

Exactly. I’m not that old…

August 9, 2012 at 4:19 pm #1091034Quote:

Thanks for a good discussion guys. Once my current transom saver goes out, I’ll be switching to the Wedge design. As others have mentioned, the transom takes a much harder beating on the water than it would on any trailer ride.

I have to respectfully disagree on this. I’ve personally seen a boat snap it’s transom hitting a pot hole in a parking lot. They were using the motor supplied tab that flips down. (similar to the wedge in support location).

Have you ever ridden in your boat while being tailored? I have sat in my boat while getting pulled out of a launch and hit pot holes on the way out. I’m certain the shock applied to the boat far exceeded any stress I’ve ever put on it in the water. Again this is opinion.

I sent this thread to some of my engineer friends and they just laughed.

FACT: The farther your support point is from the pivot the stronger it’s going to be.

The ONLY argument here is that most boats can handle the stress. The FACT of the matter is the wedge cannot and will not reduce transom stress like a traditional transom saver.

August 9, 2012 at 4:25 pm #1091039Quote:

How do you know how much stress is on a transom at trolling speed ???

I never claimed this. I wouldn’t even try, too many variables.

I claimed that not having a transom saver puts more cycles on your transom/jack plate and with aluminum, even though the amount of stress is a factor, the number of cycles are important as well.

Plus, I’m a bass guy, I don’t troll…

Crossin – eyes – FYI, with the my-wedge for my motor, I am actually tilted more. Not sure if you actually tested the one for yours.

August 9, 2012 at 4:26 pm #1091040Quote:

http://www.youtube.com/watch?v=NdSOOTUgauo&feature=youtu.be

If we all believed commercials, we’d all own ETec motors

August 9, 2012 at 5:38 pm #1091073

August 9, 2012 at 5:38 pm #1091073Think about this, when you hit a wave, say a 3 footer at 20 mph… how much stress do you think it puts on your transom ? Now put 200 of these in a row….

Get in my boat on certain days on Mille Lacs and I will have you & I either barfing or crying uncle in about 5 minutes. I think I could ride in the back of my boat down the road, all the way to Florida

Get in my boat on certain days on Mille Lacs and I will have you & I either barfing or crying uncle in about 5 minutes. I think I could ride in the back of my boat down the road, all the way to Florida  August 9, 2012 at 5:54 pm #1091078

August 9, 2012 at 5:54 pm #1091078Quote:

FACT: The farther your support point is from the pivot the stronger it’s going to be.

True, but irrelevant here.

Quote:

The FACT of the matter is the wedge cannot and will not reduce transom stress like a traditional transom saver.

Incorrect.

This debate has been going on for years, and it still amazes me how people cannot grasp the concept that maybe, just maybe, someone figured out how to make a better mouse trap. It’s downright silly is what it is.

August 9, 2012 at 6:00 pm #1091079I did a bit of an impromptu test, my drink spilled while being bounced around over 3 foot waves, and my drink spilled while getting towed to the fish cleaning shack across the pot hole filled parking lot. Therefore through deduction my carpet gets wet no matter what. And quit giving Suzuki any new ideas.

August 9, 2012 at 6:01 pm #1091080Quote:

Think about this, when you hit a wave, say a 3 footer at 20 mph… how much stress do you think it puts on your transom ? Now put 200 of these in a row….

Get in my boat on certain days on Mille Lacs and I will have you & I either barfing or crying uncle in about 5 minutes. I think I could ride in the back of my boat down the road, all the way to Florida

Get in my boat on certain days on Mille Lacs and I will have you & I either barfing or crying uncle in about 5 minutes. I think I could ride in the back of my boat down the road, all the way to Florida

It certainly gets a shock load, but also realize that the transom is being preloaded by the thrust of the prop. This will absorb some of the shock and in my opinion, has less shock than trailering. Not to mention that trailering will likely put 90% of the shock cycles compared to being on the water.

For you guys that are engineers, I’ve very suprised that you assume the benefits without any real hard test data.

Here’s what I’ve learned from the overall opinion of this thread:

Transom savers don’t really provide any benefit

Oh, FYI… My boat will be heading up to Crestliner this winter for some warranty transom repair. I used the tilt tab on my tilt the first 3-4 years of owing it. I have no way of knowing what the actual cause is, but it can’t be ruled out.

August 9, 2012 at 6:43 pm #1091086Quote:

For you guys that are engineers, I’ve very suprised that you assume the benefits without any real hard test data.

Engineers don’t have enough spare time to get hard data for a discussion like this. That’s ridiculous. We’re spending our time doing Waterfowl AIS studies.

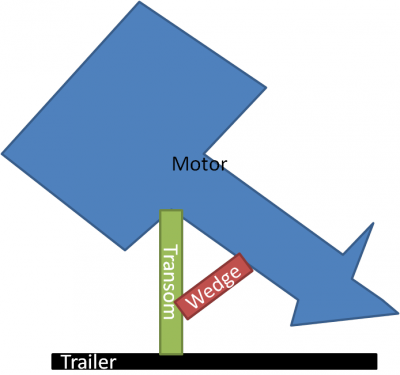

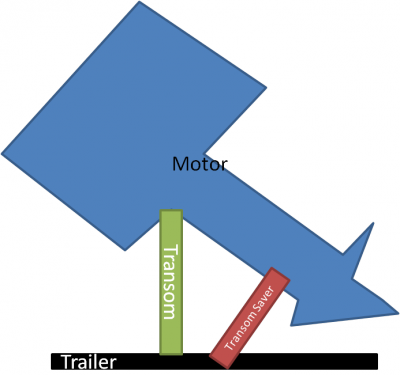

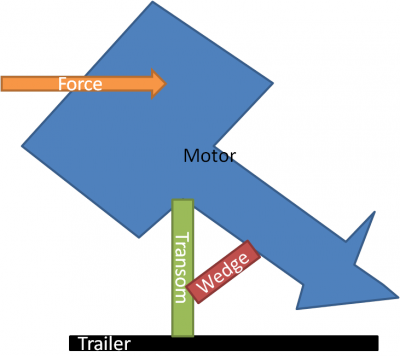

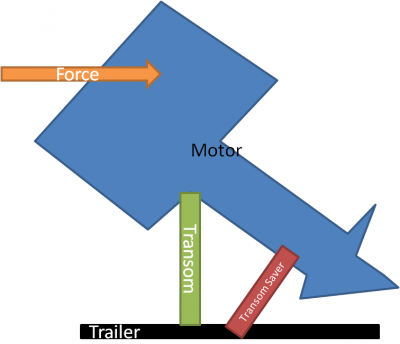

So Danno, I apologize for the pictures but, you’re saying these two diagrams are equivalent???

In simple terms, in the third pic you will see that with a force applied perpendicular to the transom upon the motor that there will be a moment generated on the transom of the Force times the distance to the bottom of the transom plus a shear force equivalent to the force.

In the fourth pic the moment and the shear force will be shared by the transom and the transom saver.

I don’t deny that the wedge helps the transom but I strongly contend that the transom saver does more for your transom than the wedge by a long shot.

Whether it matters or not, I don’t know. but I do know this, my brand new wedge is for sale if you want to buy it.

August 9, 2012 at 6:51 pm #1091096

August 9, 2012 at 6:51 pm #1091096I will say no…. the second scenario brings in another issue… a third point of contact, that may or may not move in unison with the other 2 static points of contact

Here is another question…. do either of these “savers” stop the motor from bouncing up ???

Which as we all know, what goes up..must come down.August 9, 2012 at 6:57 pm #1091097

Which as we all know, what goes up..must come down.August 9, 2012 at 6:57 pm #1091097Quote:

Here is another question…. do either of these “savers” stop the motor from bouncing up ???

That’s a good point however, gravity is helping keep them down and I actually trim my engine into the transom saver putting a force downward.

August 9, 2012 at 7:17 pm #1091107Engineers aren’t always right.

Instead of the Force being on a horizontal plane pushing of the top front of the engine, it should be from the top down away from the pivot point with the most force being generated at the skag end.

The only force that’s in effect in those photos are from air/wind.

Now can someone print me a degree?

August 9, 2012 at 7:31 pm #1091115

August 9, 2012 at 7:31 pm #1091115Quote:

Engineers aren’t always right.

Non-engineers always take engineers arguments out of context.

It is a simplification of the problem to illustrate the issue.

In real life during transportation there will likely be forces/moments in all directions at differing times.

And by the way, which way does the force point on flat ground during acceleration/deceleration of your vehicle?

August 9, 2012 at 7:50 pm #1091121

August 9, 2012 at 7:50 pm #1091121Quote:

I will say no…. the second scenario brings in another issue… a third point of contact, that may or may not move in unison with the other 2 static points of contact

Here is another question…. do either of these “savers” stop the motor from bouncing up ???

Which as we all know, what goes up..must come down.

Which as we all know, what goes up..must come down.

Is that what the bungee cord around my lower unit does?

August 9, 2012 at 7:58 pm #1091126

August 9, 2012 at 7:58 pm #1091126Quote:

Figured I would get a rise out of more then one engineer.

Non-engineers always try to cover their

with comments like these too…

with comments like these too… August 9, 2012 at 8:16 pm #1066710

August 9, 2012 at 8:16 pm #1066710Quote:

Yeah, that and some old anchor rope and mono…

Yeah, that and some old anchor rope and mono…

dont forget the braid from my prop too

August 9, 2012 at 9:36 pm #1091157

August 9, 2012 at 9:36 pm #1091157Quote:

So Danno, I apologize for the pictures but, you’re saying these two diagrams are equivalent???

Yes.

You are assuming there is a vertical force component (other than gravity) to the lower unit (i.e. bouncing), and that’s why this entire conversation always goes off on a tangent….people imagine that the engine is bouncing all over the place.

If that were the case then yes, I would rather have the bar type. But the simple fact remains that if there is little to no movement they both do the same job because when there is no bouncing it is identical to the boat sitting in your garage not moving. The engine and boat are “one”.

If you have an engine that doesn’t pull down securely via the hydraulics and bounces down the road I would use the bar type. My engine pulls down tight and doesn’t budge. YMMV.

Once again, if the engine doesn’t move or move excessively, then the wedge performs the same function as the bar type.

Quote:

Whether it matters or not, I don’t know. but I do know this, my brand new wedge is for sale if you want to buy it.

No thanks. I already have one I don’t use.

You must be logged in to reply to this topic.